How would life be like if you felt as though you could never fully catch your breath?

If the simple act of breathing that should be effortless to carry out became more difficult as the days went by? Try to imagine, if you’re someone who practising a healthy lifestyle and never smoke a single cigarette in your life yet still experiencing all those symptoms of breathing difficulty. Unbelievable, right? However, in reality, many workers with silicosis as a result of their working properties are facing this health problem. Silicosis is a type of long-term lung disease caused by inhaling large amounts of crystalline silica dust, usually over a long period of time. The workers contracted silicosis from their workplace by unintentionally breathing in dangerous silica particles in the dust from concrete and other stone products.

Unfortunately, silicosis is not the only respiratory disease that workers are exposed to. Lung cancer and mesothelioma can be a result of asbestos exposures. While other inhaled particulates can lead to more medical problems. For instance, chemical vapours and fumes can cause respiratory damage and disease. No one deserves this to happen. Your duty is to ensure workplace safety and health and that your employees are properly protected from respiratory hazards.

Source of image: NIFS

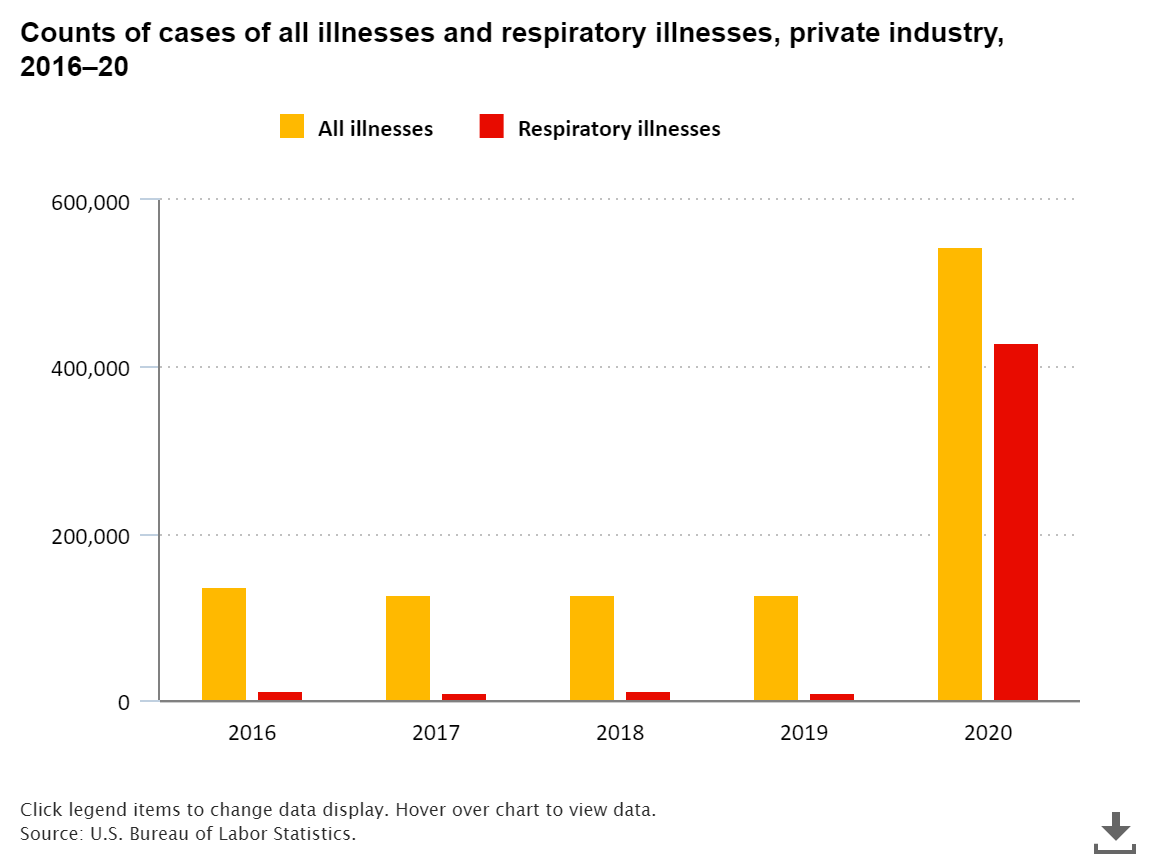

Employer-Reported Respiratory Illnesses Increased Nearly 4,000 Percent in 2020

The number of cases of respiratory illness increased by nearly 4000% from 10,800 (2019) up to 428,700 (2020). This indicates the escalation in the rate of industrial respiratory illness from 1.1 cases per 10,000 full-time equivalent workers in 2019 to 44.0 cases per 10,000 full-time equivalent workers in 2020.

Understanding Respiratory Hazards

Source of image: canva.com

Unfortunately, it can be difficult to predict when someone may be exposed to hazardous levels of a respirable hazard. It is impossible to tell by looking at a dust cloud whether it exceeds the permissible exposure limit (PEL) established by OSHA. The exposure can only be determined by sending the air sample to laboratory for testing. This doesn’t mean that your operations need to stop whenever there is a cloud of concrete dust; as an employer, you should consult a workplace injury prevention expert to determine whether air sampling is needed whenever you suspect the exposure level exceeds the substance’s PEL.

Some other workplace exposures that respiratory protection might be needed:

- Chemical hazard exposures

- Smoke

- Dusts and nuisance dusts

- Silica-containing materials exposures

- Painting operations

- Welding/ grinding/ metal-working operations

Workplace Safety Management Programs: Protect Workers Against Respiratory hazards

Source of image: canva.com

What can employers do to secure their workers from respiratory hazards? As usual, the first line of protection is to eliminate or minimise the exposure to hazards through engineering and administrative controls. For instance, to reduce exposures, the recent Silica standards include specific engineering controls based on the task performed.

Besides, administrative controls are able to control and minimise an employee’s exposure through employee scheduling and operational procedures. The last yet important line of defence, as always, is personal protective equipment (PPE). PPE for respiratory protection needs to be specifically selected based on the exposures that employees will face.

A written respiratory protection program must be in place when your workers need to wear respirators, either due to employer policy or to unavoidable exposures exceeding the PELs. Moreover, employees must be trained on the plan and the proper usage of the respirator including its limitations and proper maintenance. All these are to ensure the safety of the workers when they need to expose to potentially life-threatening respirable substances.

Respiratory Protection: Respiratory Protective Equipment (RPE)

Source of image: canva.com

Respiratory Protective Equipment (RPE) is a type of Personal Protective Equipment (PPE) that is used to protect the wearer from the inhalation of hazardous substances in the workplace air. RPE should be used only as a last resort within the hierarchy of control measures, namely Elimination, Substitution, Engineering Controls, Administrative Controls, and Personal Protective Equipment (PPE).

Firstly, employers are required to attempt the elimination of the hazard at the source. RPE should be used after all other reasonably practicable control measures have been taken. Wearing inappropriate RPE for work can be more dangerous as the workers may have a false sense of security when using the wrong RPE.

Respiratory Protective Equipment (RPE) not worn or selected appropriately is totally ineffective and may give the user a false sense of protection.

Respirators protect workers against oxygen deficit environments, harmful gases including dusts, fogs, smokes, mists, vapours, and sprays. These hazards may seems small yet can cause cancer, respiratory diseases, lungs impairment, or even death in long-term contact. Compliance with the Respiratory Protection Standard from OSHA, hundreds of deaths and thousands of illnesses each year can be prevented.

Two Types of Breathing Protection

.png?width=741&name=2%20types%20of%20breathing%20protection(2).png)

Respirators protect the wearer in two basic approaches. First, is the filtering protection by filtering and removing the contaminants from the surrounding air that passes through it. This type of respirator is used where a sufficient oxygen level is present and known contaminants can be captured in the filter. Filters must not be used where the contaminant concentrations are at an immediate life-threatening level. Examples of filter protection are half and full face masks with replaceable filters as well as powered-assisted filter protection for half and full masks or hoods, visors and helmets. For contaminants in gas form, appropriate gas filter are used with active carbon that absorbs the gas. It is important to set up a filter replacement policy as the breakthrough starts when the filter becomes saturated. Particles such as dust, smoke, and mist are captured in particle filters. As the degree of clogging rises, breathing resistance increases and the filter must be replaced if there is any damage or breathing difficulty. Combination of filters can be used in the presence of both particles and gas.

While the breathing apparatus supplies the user with air from an independent source, via cylinders with compressed air or breathable air from a compressor. Continuous flow airline equipment with hoses is used in half and full face masks, hoods, helmets, and visors. Compressed air-fed breathing protection may be used in all environments suitable for filters and in which a higher level of protection is required. Some substances cannot be absorbed by filter, and in such cases, compressed air-fed breathing protection is the only alternative.

Workplace Safety Management Plans for Respiratory Protection

It should be clear by now that respiratory protection is no small matter. It takes a significant amount of time and effort to be implemented properly. This requires understanding communications with the involved workers too. They need to be aware of the types of exposure and the effects if kept on in contact with the contaminants without any proper RPE. Thus, make sure that your respiratory exposures are properly evaluated, and implement s workplace safety management plan and respiratory protection program when needed. It is your responsibility to ensure the safety and health of your workers.

Need help? Contact Safetyware- Malaysia’s leading safety & health solutions provider with over 30 years of experience that provide one-stop OSH products and services. We strive to make your workplace safer, reduce injuries, save your money and increase your productivity!